Smart Bin Applications in Robotics, Valve Manufacturing, Power & Energy Storage Industries

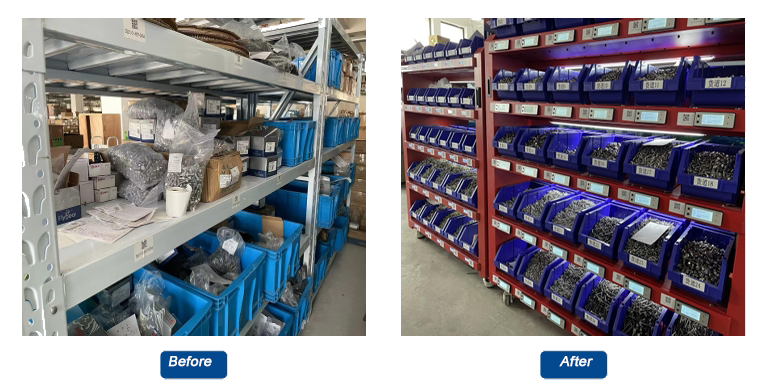

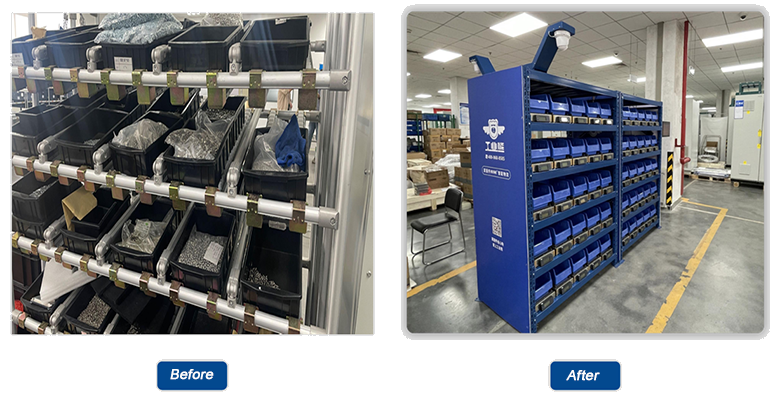

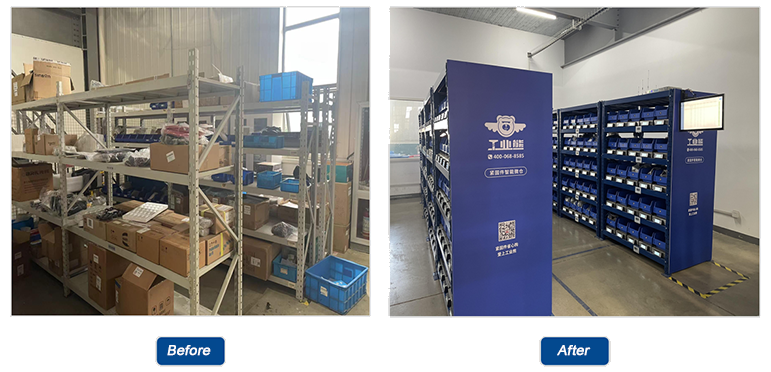

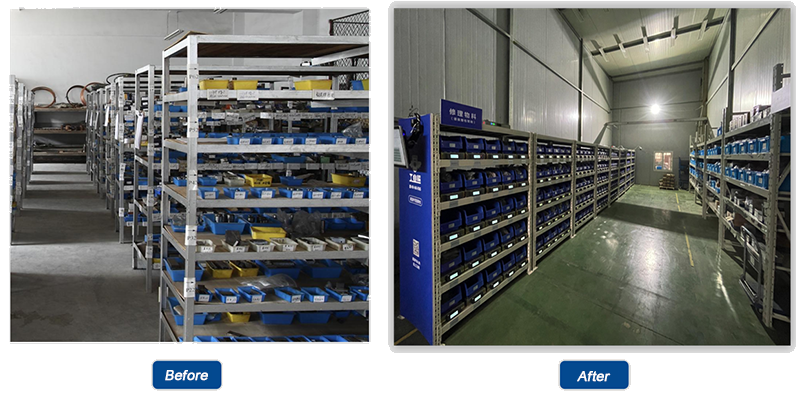

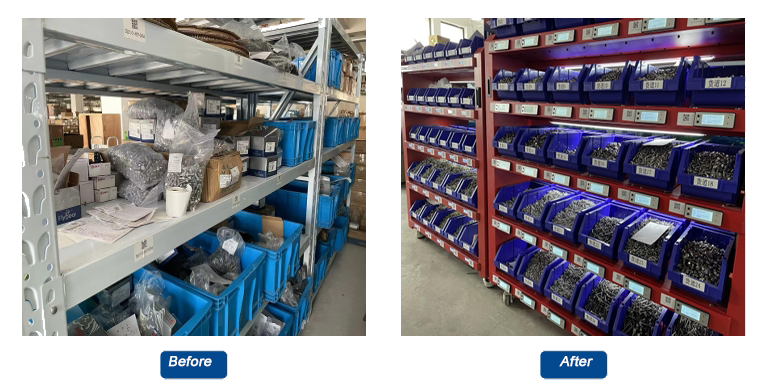

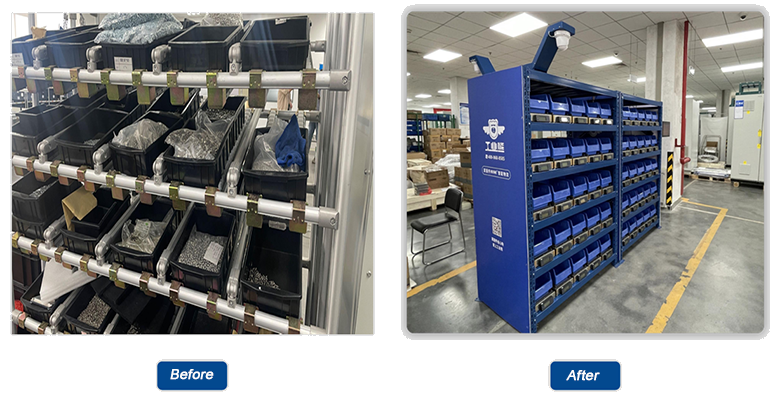

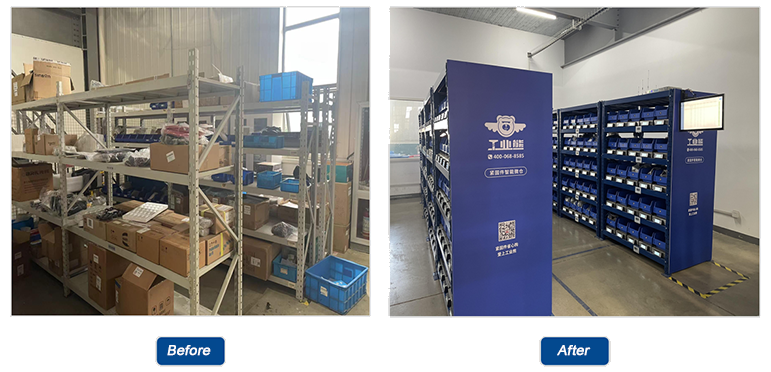

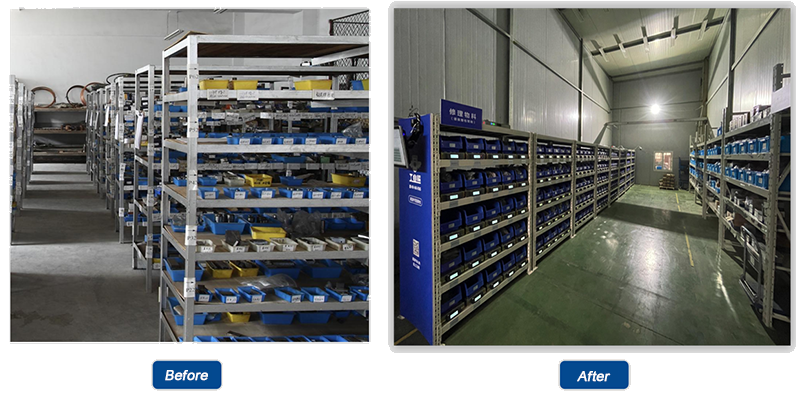

Across the industrial world, production efficiency and material accuracy determine whether factories can meet delivery schedules and maintain stable quality. Robotics, valve manufacturing, power facilities, and the fast-growing energy storage sector are industries with complex Bill of Materials (BOM), frequently used MRO parts, and strict traceability requirements. Smart Bin systems provide a unified digital solution that brings material visibility, accountability, and automation into daily operations.

1. Robotics Manufacturing – High Precision, High Complexity, Zero Tolerance for Errors

Robotics production involves thousands of small components: screws, sensors, connectors, gear parts, wiring materials, and calibration tools. A missing part or incorrect pick can lead to assembly delays or functional defects. Smart Bins solve these issues by ensuring:

-

Accurate SKU-level tracking for every consumable and small assembly part.

-

Real-time stock visibility for high-frequency components used on the robotic assembly line.

-

User accountability to ensure operators retrieve materials according to work orders.

-

Reduced downtime with point-of-use Smart Bins placed next to assembly stations.

The result is a smoother assembly flow, fewer missing materials, and higher first-pass yield—critical factors in robotics manufacturing.

2. Valve Manufacturing – Managing Metal Parts, Fixtures, and Specialized Tools

The valve industry requires precise machining, strict quality control, and large inventories of metal parts such as bolts, seals, gaskets, sleeves, and custom fasteners. Smart Bin systems help valve factories maintain process stability by providing:

-

Digital traceability for mission-critical parts and calibrated tools.

-

Controlled issuance for tools that influence machining precision.

-

Optimized replenishment to keep machining and inspection lines stocked without excess inventory.

-

Compliance support for quality systems like API, ISO, and PED certifications.

Through Smart Bins, valve factories avoid production delays, reduce scrap caused by tool-wear issues, and maintain consistent machining accuracy.

3. Power Facilities – Safety, Standardization, and 24/7 Operational Reliability

In power plants, substations, and electrical distribution networks, maintenance materials must be available instantly. Downtime in these facilities can bring financial loss and safety risks. Smart Bins ensure operational continuity through:

-

24/7 autonomous access for maintenance crews without relying on storeroom personnel.

-

Strict access control for insulated tools, PPE, and safety-critical components.

-

Real-time consumption logs to support inspection records and safety audits.

-

Distributed Smart Bins across large facilities for rapid response.

With Smart Bin systems, power operations maintain stronger compliance, quicker repair cycles, and safer working environments.

4. Energy Storage Industry – Fast Growth Requires Fast, Lean Material Flow

The energy storage sector has surged in recent years, bringing new manufacturing capacity and high material complexity. Battery assembly, BMS manufacturing, and ESS system integration rely on precise small parts, connectors, modules, and MRO materials. Smart Bins help manage the high-speed material turnover in:

-

Battery pack assembly lines that need uninterrupted material supply.

-

Component verification workflows requiring batch and lot tracking.

-

Flexible operations powered by mobile Smart Bin units supporting multi-station layouts.

-

Lean replenishment driven by real-time data from the NVMI platform.

By eliminating manual counting and uncontrolled withdrawals, Smart Bins support the rapid, high-quality output required in energy storage manufacturing.

Why Smart Bins Fit These Industries so Well

Across robotics, valve manufacturing, power facilities, and energy storage, several shared challenges exist: material complexity, usage variability, and demand for traceability. Smart Bins provide a scalable infrastructure that addresses all these needs:

-

Real-time visibility across hundreds or thousands of SKUs.

-

Secure, role-based access to protect high-value or safety-critical materials.

-

Fast picking and returns to support high takt-time workflows.

-

Data-driven replenishment that prevents stockouts and reduces excess inventory.

-

Full digital traceability for audits, compliance, and quality management.

These capabilities make Smart Bins an ideal building block for modern, digital industrial logistics.

Conclusion

Smart Bin systems are transforming material management across multiple advanced manufacturing industries. Robotics factories gain higher precision, valve manufacturers gain tighter process control, power facilities boost operational reliability, and energy storage manufacturers achieve leaner logistics. As industrial digitalization accelerates, Smart Bins are becoming an essential infrastructure element that ensures accuracy, efficiency, and traceable material flow.