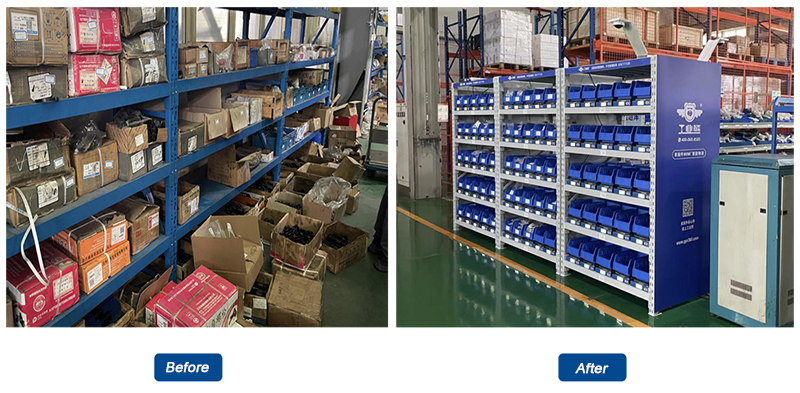

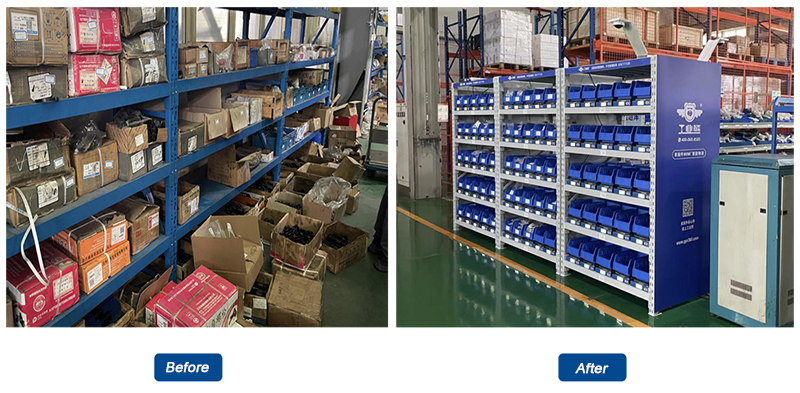

Electric Motor Powertrain Industry: Error-Proofing System Improves Assembly Precision

Background — torque deviation and mixed grades affecting EV drive motor assembly

A motor manufacturer producing electric-vehicle drive motors experienced fluctuations in abnormal-noise rates due to torque deviations when tightening precision bolts. Under the traditional model, manual material selection errors led to frequent mixing of bolt strength grades, causing a high rework rate for certain motor batches. After introducing the Bear Bit NVMI® solution, the situation improved markedly:

Error-proof picking mechanism

-

When workers swipe their badges to collect bolts, the system uses LED indicators to precisely point to the correct bin location.

-

It verifies batch-to–work-order compatibility to prevent mixing products of different strength grades.

Electronic kanban collaboration

-

Electronic displays on the assembly line show real-time material consumption for each workstation.

-

When a station’s bolt inventory falls below a threshold, the system automatically dispatches replenishment to the line-side warehouse, significantly improving delivery timeliness.

Results

-

Assembly first-pass yield increased significantly.

-

Rework rates dropped substantially.

-

Annual quality-related costs were greatly reduced.