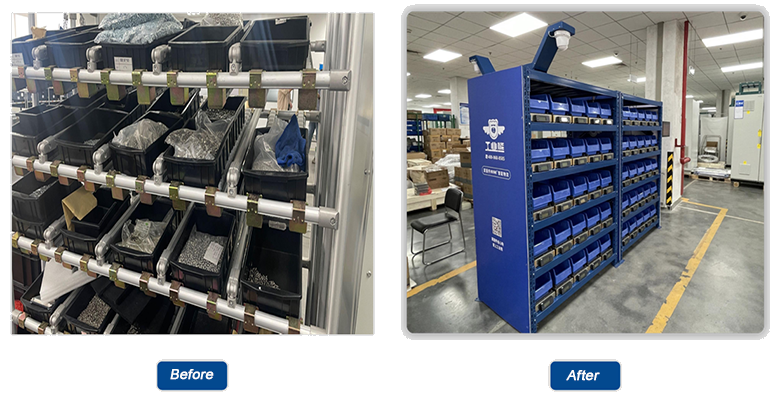

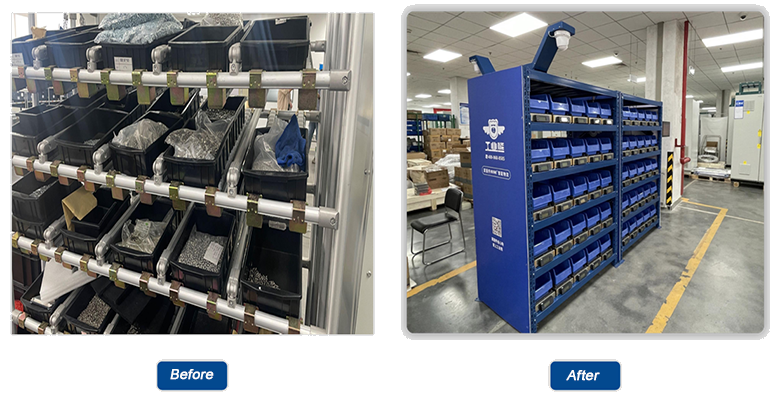

Power Grid Systems: Error-Proofing System Solves Transformer Bolt Assembly Challenges

Background — insufficient precision in high-strength bolt management during transformer winding assembly

A leading transformer manufacturer long suffered from inadequate management precision for high-strength bolts during winding assembly. Under the traditional approach, multiple bolt types were managed with manual ledgers, and specification confusion frequently caused rework with significant single-incident costs. After adopting the Bear Bit NVMI® solution, the smart micro-warehouse system achieved precise control:

Dynamic inventory alerts

-

Electronic tags display real-time inventory levels of critical bolts.

-

When a specific type of prevailing-lock nut falls below the safety threshold, the system automatically issues replenishment orders to the supplier cloud platform and simultaneously notifies the production scheduling center.

Stagnant material reduction

-

The IMOD system analyzed historical usage data and found that a certain type of copper washer had extremely low annual consumption.

-

It recommended that suppliers adjust replenishment cycles, significantly reducing that item’s share of inventory.

Traceability and results

-

After implementation, assembly rework rates dropped significantly and emergency procurement frequency decreased sharply.

-

Area occupied by stagnant materials was noticeably reduced and annual total costs were substantially lowered.

-

With full-process RFID tracking, the lifecycle data for each bolt—from receipt into inventory to final assembly—is fully traceable, markedly improving product quality traceability efficiency.