Power Industry: Smart Cabinets Protect Substations with 24/7 Operations

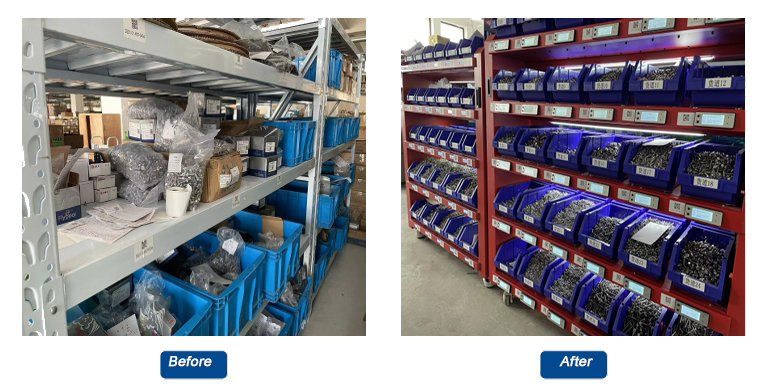

Background — chaotic tool management during substation maintenance

In a substation maintenance scenario at an East China power grid company, management of various tools and safety equipment was chaotic. Insulated gloves, voltage testers and other safety tools were often “on the books but not on site” due to manual inventory errors, causing repeated delays and prolonged outage repairs.

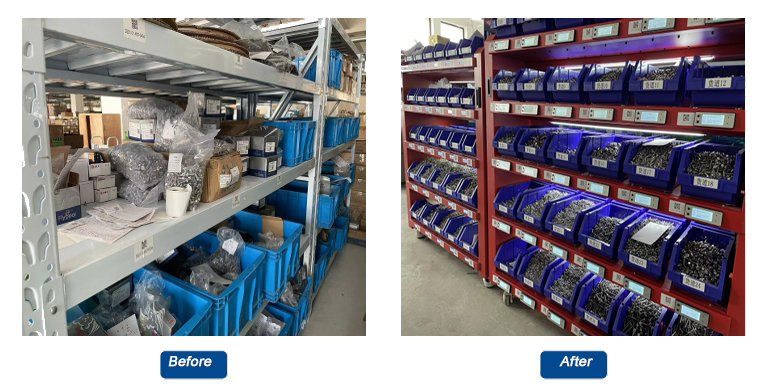

Bear Bit® Solution — smart tool cabinet + SaaS platform

The Bear Bit NVMI® solution integrates intelligent tool cabinets with a cloud-based SaaS platform to modernize tool and equipment management.

Rapid repair response

-

When an emergency repair work order is triggered, the system automatically generates a tool list and lights up indicators to guide picking, dramatically shortening the time to retrieve tools.

-

During typhoon season, a substation outage was repaired faster because required tools were supplied on time, significantly reducing downtime.

Refined cost control

-

Usage of each torque wrench is recorded down to the second; data analysis revealed that a particular wrench model had low utilization.

-

After adjusting procurement volumes based on real usage data, the company achieved substantial annual procurement savings.

Measurable results

-

Manual inventory time was greatly reduced.

-

Compliance rate for safety tools reached 100%.

-

Annual operations and maintenance costs were lowered.