Pump & Valve Industry: Smart System Breaks the Bottleneck of Slow-Moving Materials

Background — high slow-moving rate of Class C parts in ball valve production

A large pump and valve manufacturer faced a high slow-moving rate of Class C parts (such as sealing gaskets and springs) in ball valve production. Under the traditional model, demand forecasting errors led to significant annual overstock of a specific O-ring model. The Bear Bit NVMI® solution modernizes management through demand forecasting plus dynamic replenishment.

Consumption model analysis

-

The IMOD system identified that sealing gaskets for a certain ball valve model had low average monthly usage.

-

It recommended that the supplier adjust replenishment cycles, resulting in a substantial reduction of that item’s inventory.

Issuance permission control

-

A badge-based picking system enforces role-based access for materials.

-

In one workshop, an attempt to overdraw sealing rings was blocked by the system, avoiding recurring monthly waste.

Results

-

The slow-moving rate of Class C parts dropped significantly.

-

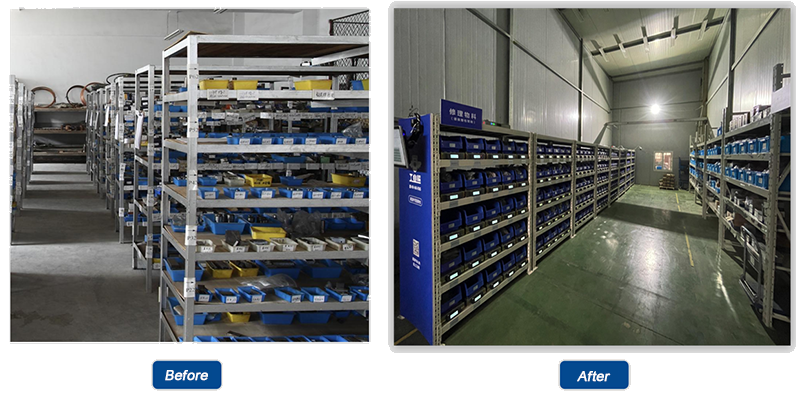

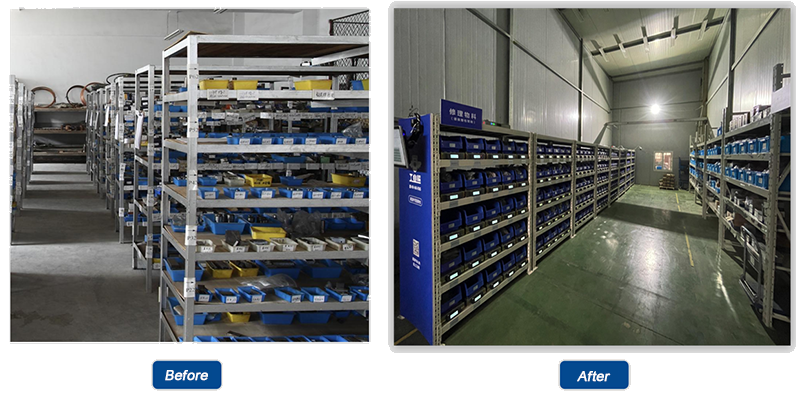

Warehouse footprint was noticeably reduced.

-

Annual inventory holding costs decreased substantially.