Rail Industry: Smart Replenishment System Solves High-Speed Train Assembly Challenges

Background — fastening chaos in high-speed train bogie assembly

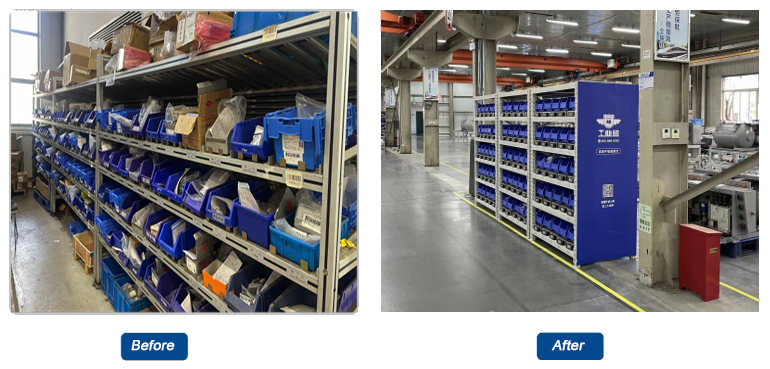

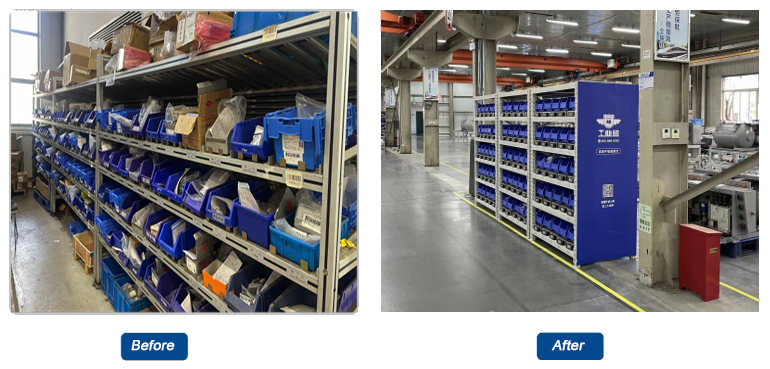

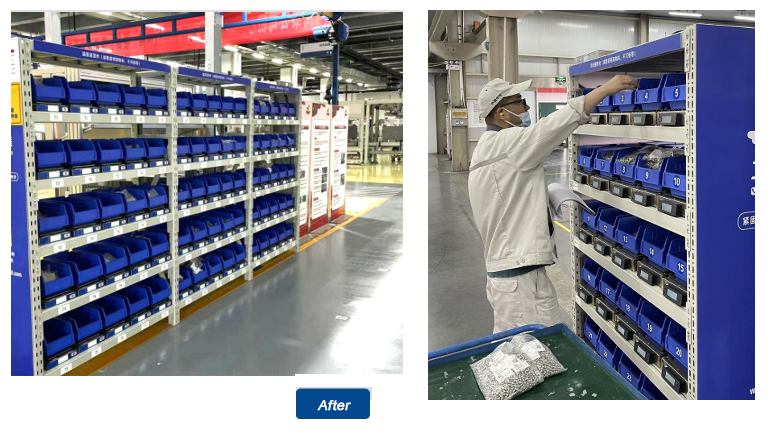

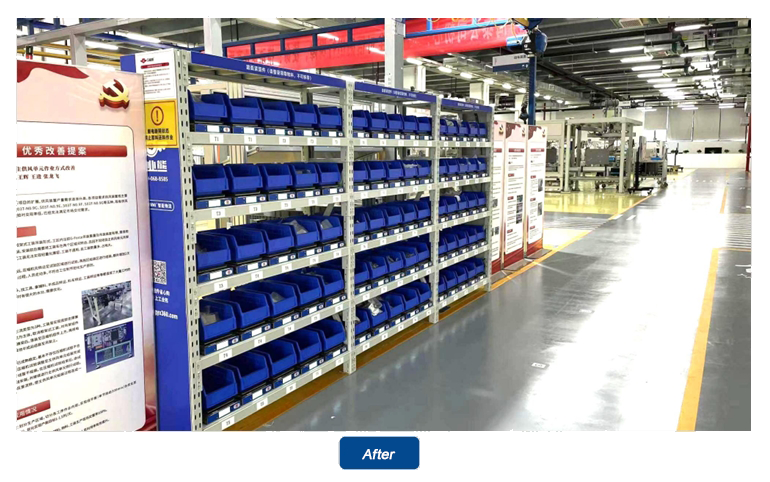

A rail equipment group faced long-standing difficulties during the assembly of high-speed train bogies due to a large variety of fastener specifications and disorderly inventory turnover. Under the traditional approach, numerous bolts and nuts were managed with manual ledgers, causing repeated production line stoppages each month from wrong or missing parts — with substantial losses per incident. After introducing the Bear Bit NVMI® solution, the smart micro-warehouse system achieved precise control:

Dynamic inventory alerts

-

Electronic tags display real-time inventory levels of critical materials such as high-strength bolts.

-

When stock falls below safety thresholds, the system automatically issues replenishment orders and pushes notifications to the supplier cloud platform.

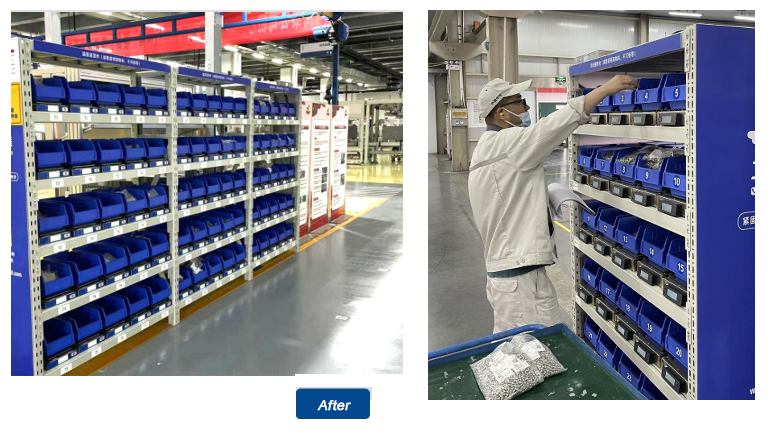

Error-proof picking

-

When workers swipe their cards to collect bolts, the system uses LED indicators to precisely point to the storage location.

-

The system verifies material batches against the work order to prevent mixing products of different strength grades.

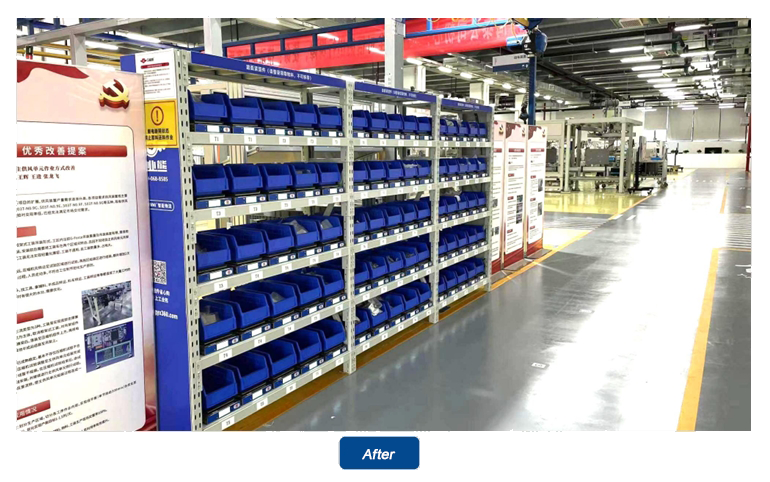

Stagnant material digestion

-

The IMOD system analyzes historical usage data and identified a specific type of lockwasher with low annual consumption.

-

It recommended that the supplier adjust replenishment cycles, significantly reducing that item’s inventory share.

Results

-

Emergency procurement frequency in the workshop dropped sharply.

-

Area occupied by stagnant material was significantly reduced.

-

Assembly efficiency improved markedly and annual total costs were substantially lowered.