Robotics Industry: Digital Management Enables High-Precision Assembly

Background — strict requirements for micro fastener control in joint module assembly

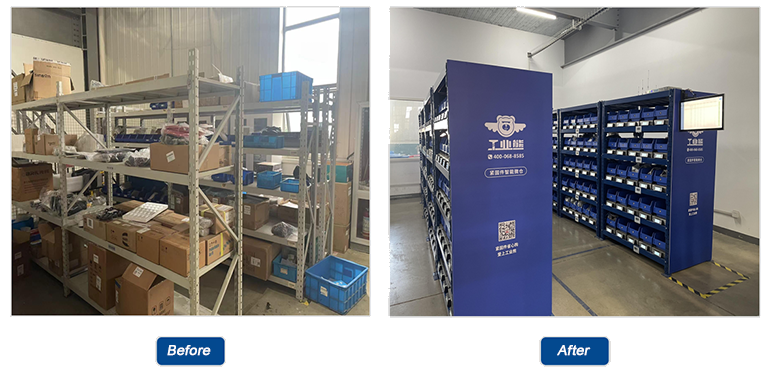

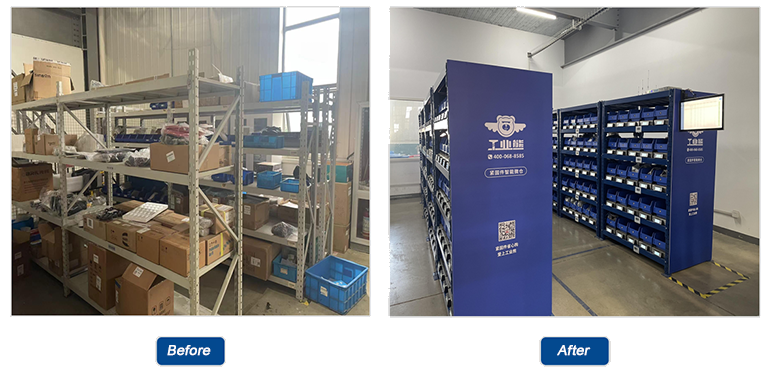

A collaborative robot manufacturer faced exacting precision requirements for micro fasteners during joint module assembly. Under the traditional approach, shoulder screws with tight tolerances were sometimes mis-sorted by hand, causing fluctuations in yield rates. After introducing the Bear Bit NVMI® solution, the company achieved significant improvements:

Vision-based error prevention

-

The smart cabinet automatically recognizes parts, achieving very high sorting accuracy.

-

One batch was intercepted by the system because its engraving was blurred, preventing a large-scale rework event.

Dynamic demand matching

-

The IMOD system predicts needs from historical production data; when orders for a certain model of harmonic reducer rise by a set percentage, it automatically triggers early replenishment of matching screws.

-

As a result, downtime waiting for parts dropped from several times per month to zero.

Electronic kanban collaboration

-

Assembly-line electronic displays show real-time material consumption at each workstation.

-

When a station’s screw inventory runs low, the system automatically dispatches replenishment to the supermarket at the line side, significantly improving delivery timeliness.

Results

-

Final assembly yield stabilized at a high level.

-

Inventory turnover rate improved noticeably.

-

Annual savings in quality-related costs were substantial.